- Get link

- X

- Other Apps

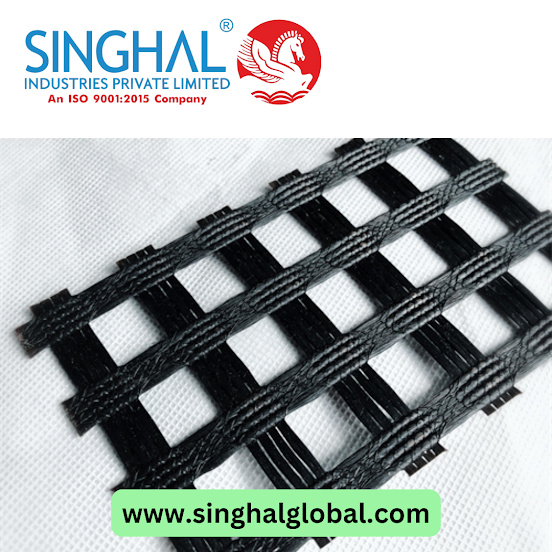

Polyester geogrid is a crucial material in the world of civil engineering and construction, known for its exceptional strength and reinforcement capabilities. Made from high-tensile polyester fibers, this geosynthetic material plays a vital role in stabilizing and strengthening soil and aggregate foundations. Whether you're involved in road construction, retaining walls, or erosion control, understanding the properties, benefits, and applications of Polyester Geogrid for Road Construction can help you make informed decisions for your projects. This comprehensive guide covers everything you need to know about polyester geogrid, including frequently asked questions (FAQs) to clarify any uncertainties.

What is Polyester Geogrid?

Polyester geogrid is a type of geosynthetic material made from polyester fibers that are woven or knitted into a grid-like structure. The material is engineered to provide high strength and stability in various civil engineering applications. Polyester geogrids are typically used to reinforce soil, prevent erosion, and improve the overall stability of structures.

Key Features of Polyester Geogrid

High Tensile Strength: Polyester geogrids are known for their high tensile strength, which helps reinforce soil and other materials effectively. This strength contributes to the stability and durability of structures.

Durability: Polyester geogrid is highly resistant to environmental factors such as UV radiation, chemical exposure, and temperature fluctuations. This durability ensures long-lasting performance in various conditions.

Flexibility: The flexible nature of polyester geogrid allows it to conform to the contours of the ground, providing consistent reinforcement and support.

Lightweight: Despite its strength, polyester geogrid is relatively lightweight, making it easy to handle and install. This characteristic contributes to cost savings and efficient project execution.

Cost-Effectiveness: Polyester geogrid provides a cost-effective solution for soil stabilization and reinforcement. Its long lifespan and minimal maintenance requirements contribute to overall project savings.

Benefits of Polyester Geogrid

1. Enhanced Soil Stabilization

One of the primary benefits of Polyester Geogrid Reinforcement is its ability to stabilize soil. By distributing loads evenly and reducing soil deformation, polyester geogrid helps prevent soil erosion and improves the load-bearing capacity of foundations. This stabilization is particularly valuable in areas with weak or unstable soils.

2. Improved Load Distribution

Polyester geogrid effectively distributes loads across a larger area, reducing localized stress and preventing soil settlement. This improved load distribution is crucial for the stability of roads, pavements, and retaining walls.

3. Prevention of Erosion

In erosion-prone areas, polyester geogrid acts as a reinforcement to prevent soil erosion. The grid structure helps hold soil in place, reducing the risk of washouts and maintaining the integrity of slopes and embankments.

4. Increased Structure Lifespan

By reinforcing soil and improving load distribution, polyester geogrid extends the lifespan of structures such as roadways, embankments, and retaining walls. The reduced risk of soil failure and deformation contributes to the long-term stability of these structures.

5. Ease of Installation

Polyester geogrid is relatively easy to install compared to other reinforcement materials. Its lightweight and flexible nature simplifies handling and placement, reducing labor and installation time.

6. Environmental Benefits

Polyester geogrid contributes to environmental sustainability by reducing the need for additional construction materials. By stabilizing soil and preventing erosion, it minimizes the impact on surrounding ecosystems and helps preserve natural resources.

Applications of Polyester Geogrid

1. Road Construction

In road construction, polyester geogrid is used to reinforce subgrade soils and improve load-bearing capacity. It helps distribute traffic loads evenly, reducing the risk of pavement distress and extending the lifespan of roads.

2. Retaining Walls

Polyester geogrid is commonly used in the construction of retaining walls to provide additional stability and support. The geogrid reinforces the soil behind the wall, preventing sliding and ensuring structural integrity.

3. Erosion Control

For erosion control projects, polyester geogrid helps stabilize slopes and embankments, preventing soil loss and maintaining vegetation. It is often used in combination with other erosion control measures to achieve optimal results.

4. Landfills

In landfill construction, polyester geogrid is used to reinforce the foundation and prevent settlement. It provides stability to the landfill liner and improves overall performance by distributing loads evenly.

5. Airport Runways

Polyester geogrid is employed in the construction of airport runways to enhance load distribution and stability. It helps prevent runway deformation and extends the lifespan of the runway surface.

6. Green Roofs

In green roof applications, polyester geogrid is used to provide structural support for the growing medium and vegetation. It helps distribute loads and stabilize the roof structure, contributing to the overall health of the green roof system.

Installation and Handling of Polyester Geogrid

Handling and Storage

Proper handling and storage of polyester geogrid are essential to maintain its performance and integrity. Store the geogrid in a dry, cool place away from direct sunlight and avoid exposure to chemicals or excessive moisture. Handle it carefully to prevent damage or deformation.

Installation Process

Site Preparation: Prepare the site by leveling the ground and removing any debris or vegetation. Ensure that the subgrade is compacted and stable before installing the geogrid.

Placement: Unroll the polyester geogrid and place it on the prepared surface. Ensure that the geogrid is aligned correctly and overlaps are properly arranged if multiple layers are used.

Securing: Secure the geogrid in place using appropriate anchoring methods, such as stakes or pins. Ensure that the geogrid is taut and free of wrinkles or folds.

Backfilling: After placement, backfill the geogrid with the required materials, such as soil or aggregate. Ensure that the backfill is compacted evenly to provide proper support and reinforcement.

Monitoring: Monitor the installed geogrid to ensure that it remains in good condition and performs as expected. Address any issues promptly to maintain the effectiveness of the reinforcement.

Conclusion

Polyester geogrid is a powerful reinforcement material that plays a vital role in modern civil engineering and construction projects. Its high tensile strength, durability, and versatility make it an ideal choice for soil stabilization, load distribution, and erosion control. By understanding the features, benefits, and applications of polyester geogrid, you can make informed decisions for your projects and achieve successful outcomes. Whether you're working on road construction, retaining walls, or erosion control, Polyester Geogrid Installation offers a reliable and effective solution to meet your reinforcement needs.

FAQs about Polyester Geogrid

1. What is polyester geogrid made of?

Polyester geogrid is made from high-tensile polyester fibers that are woven or knitted into a grid-like structure. The polyester material provides strength, durability, and flexibility for reinforcement applications.

2. What are the main applications of polyester geogrid?

Polyester geogrid is used in various applications, including road construction, retaining walls, erosion control, landfills, airport runways, and green roofs. Its versatility and strength make it suitable for a wide range of civil engineering projects.

3. How does polyester geogrid improve soil stabilization?

Polyester geogrid improves soil stabilization by reinforcing the soil structure and distributing loads evenly. This reduces soil deformation and prevents erosion, contributing to the stability and durability of the foundation.

- Get link

- X

- Other Apps

Comments

Post a Comment